As budget time comes round, now is the time to consider capital expenditure projects that will ensure business continuity both now and in the long term future.

Whether you’re planning a large control system upgrade, making updates to supporting IT infrastructure, or simply running production, your SCADA systems provide invaluable information. This is why staff at all levels need to be appropriately trained.

Three critical groups who are increasingly being asked to interact with SCADA systems are:

- IT professionals

- Engineers and Operations/Asset Managers

- Electricians and Maintenance Technicians

Here’s why these three vital groups stand to benefit from SCADA training and how to upskill them.

1. IT professionals

There’s a few reasons why IT professionals are increasingly required to acquire SCADA skills.

First, digitisation and IoT connectivity are disrupting how we view and handle SCADA systems.

Read more: 6 cross-industry applications of industrial IoT in practice

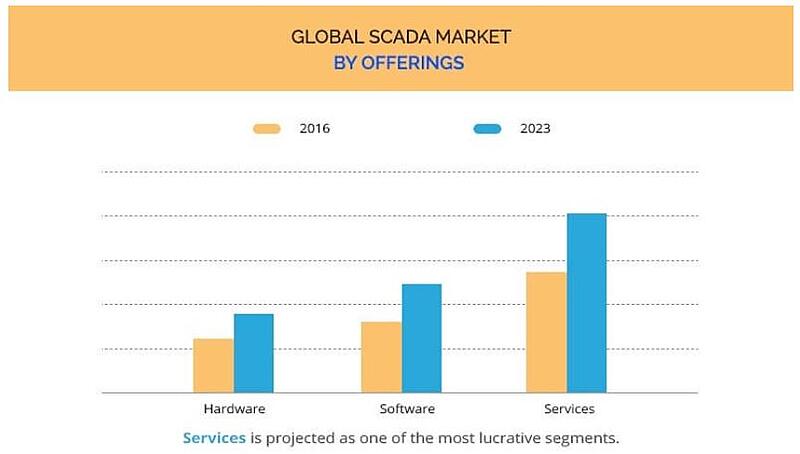

According to a 2018 Allied Market Research report, “Growth in adoption of cloud-based SCADA systems, infrastructural development such as Smart Cities & transportation, and high penetration of mobile SCADA systems drive the growth of the global SCADA market.”

The research also reports SCADA-as-a-service is set to be the biggest growth segment by 2023. Such services are likely to be managed by IT.

SCADA-as-a-service is set to be the biggest growth segment by 2023. Image: Allied Market Research

This means that more IT professionals in industrial companies will have to be proficient in both SCADA and IT-based protocols & systems.

Secondly, we’re seeing a trend towards IT and OT convergence in organisational structures. Multiple sites are now governed under one central IT department, as well as operational and engineering work also being brought under IT.

This means that IT people are suddenly acquiring responsibility for SCADA.

In the future, IT professionals will be required to understand control system concepts and how they relate with critical IT infrastructure.

"SCADA and PLC systems are managed in real-time, and they’re highly important to the production side of business – if they go down, so does production, and by extension the business," resident SAGE SCADA expert Steven Bailey explains.

Handling control system upgrades

IT also risk inheriting control systems that are now due for obsolescence upgrades. So when they need to upgrade, maintain or implement new equipment – what do they do?!

“One approach we’ve seen is for the project team to hire IT contractors to deliver control systems projects – which can be fraught with risk,” Bailey says.

“While they are experts in IT systems delivery methodology, they don’t necessarily have the control systems background to deliver a complex engineering project.”

Solve this challenge with:

a) Training

One option is to provide SCADA training to your IT department. That way you’re ensuring maintainability of your assets and fostering better understanding between IT and operational teams.

SAGE's sister company, Skills Lab offers custom SCADA and PLC training for exact site set up or foundational courses that will get IT professionals up to speed on general control system concepts or technologies.

b) Control system projects

If you’re looking to implement new equipment, upgrade an old control system, or improve remote asset monitoring, consider getting in a control system specialist to assist. With now more than 1,700 control system projects worth $150 million on-the-go at any one time, SAGE Projects has the experience to assist you in end-to-end project delivery.

We’ve noticed a shift in the point-of-engagement that reflects this convergence of IT and OT:

“Our specialists are experts at coordinating between the IT team, the engineers or maintenance personnel.”

2. Engineers and Asset/Operations Managers

Those in the industry will know that engineers and operations managers, who are already experienced SCADA users, will continue to need SCADA training throughout their careers.

There are a handful of situations that call for SCADA training for this group.

1. When a new vendor-product is rolled out: While there is a degree of similarity between SCADA systems, vendor-specific training is a must for those who jump from one vendor to another because being highly proficient at one doesn’t mean that this knowledge will seamlessly transfer across platforms.

Some most widely used systems include: Citect, ClearSCADA, Ignition, WinCC, iFIX, Cimplicity, and FactoryTalk ViewSE.

2. When there is a system upgrade: Since you typically only need to upgrade a SCADA system every 10 years or so, the changes in the operating systems and its capabilities can be drastic. It’s important to train staff on updated SCADA platforms to ensure that you are getting the most out of the upgrades.

3. When there is a business and/or technological change: A lot can change over several years – new SCADA systems and other disruptive technologies may or may not be supported by current IT infrastructure. Business changes could result in additional sites to manage, new assets to monitor, or new products to produce that will impact the choices for SCADA and PLC systems. It’s also common for businesses to pick up different pieces of equipment and control systems over time, which will all be in different life-cycle stages and versions.

This all means that experienced SCADA users will need to continuously train for multiple products and technologies that work together.

Generally, all operations and manufacturing managers – not just technical staff – should be knowledgeable about SCADA products and trends. For example, managers should know that Windows Server 2008 will be reaching end-of-life in 2019, which means critical infrastructure that supports SCADA will no longer be supported. Planning for such a change should happen now.

Solving the challenge

Each company’s mix of hardware, software, asset life-cycles and production context will dictate their exact training needs. So there are a couple of options here:

Many people go directly to the vendor for product-specific training. While there’s nothing wrong with this, be aware of the course location and content – sometimes vendor-run programs are a bit too broad brush when you may need more specificity.

Another option is to go to an automation training expert, such as Skills Lab, who offer vendor-specific training in SCADA courses designed for you. If you’d like to learn more, have a look at what Skills Lab, formerly SAGE Training, did for Pakistan’s top energy officials.

3. Electricians and maintenance technicians

Not surprisingly, the people who maintain production equipment have the most potential to use SCADA and PLC to impact production.

Maintenance and electrical works technicians who have an understanding of PLC or SCADA are more likely to troubleshoot, fault-find, and resolve control & automation issues so that specialists are only called in when they are truly needed.

In short, providing this group with SCADA training has the most potential to save the business money that would have otherwise been lost in unplanned downtime.

“As budgets get tighter, it will be increasingly valuable to have maintenance people who can bridge the gap between basic electrical and the industrial control system space,” Bailey says.

Solving the challenge

As above, organisations can opt for a vendor-run training program or enlist the services of an independent automation training expert.

Skills Lab offers foundational PLC, intermediate PLC and SCADA courses that would suit electricians' or maintenance technicians’ skills and knowledge.

Conclusion

With the SCADA market set to reach US$40.18 billion by 2024 and a whole new world of digital disruptors coming into the market, this industry is moving at a rapid pace. Having an up-to-date, industry-derived understanding of these systems will be the key to every industrial organisation’s future competitiveness.

Working training into next year’s budget will ensure that projects run without blowout, operations are continuously improving, and employees can solve their own control system issues to keep production online.

Find out how our ability to customise our training courses for PLC and SCADA systems helped provide 'invaluable, industry-derived training' to the Royal Australian Navy.