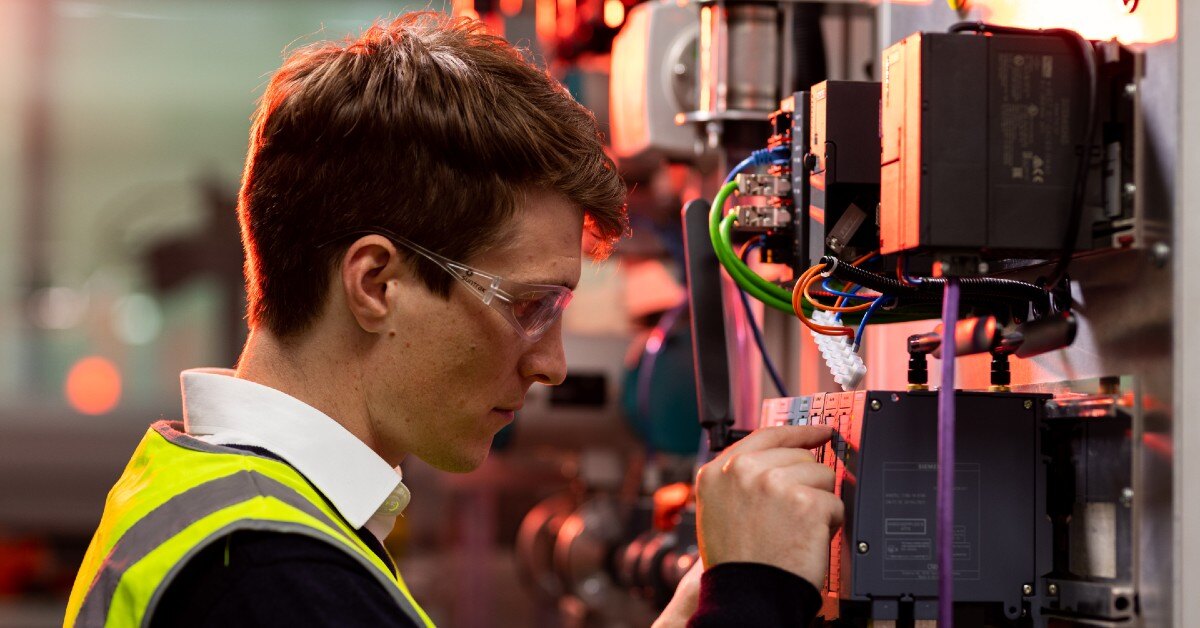

Electricians Working with Modern Industrial Automation

Master control systems with hands-on industrial automation training. Learn to configure PLCs, RTUs and troubleshoot hardware while gaining predictive maintenance skills.

Enquire nowKey Information

This micro-credential equips learners with an understanding of the different hardware used in modern control systems, as well as the ability to troubleshoot the software and the incoming and outgoing signals.

On completion, learners will be able to connect and configure common control system hardware, such as PLCs, RTUs, radios, and edge gateways, understand common industrial communication protocols including their benefits and limitations, and maintain, and fault find industrial automation hardware.

This course is best suited to electricians or those working in a similar field.

This micro-credential will involve a volume of learning of approximately 40 hours of student effort.

All course materials will be provided electronically using the Skills Lab online Learning Management System (LMS).

Breakdown of the Course/Module

Upon completion, learners will be able to:

- Connect and configure common control system hardware, such as PLCs, RTUs, radios and edge gateways

- Understand common industrial communication protocols, including their benefits and limitations

- Maintain and fault find industrial automation hardware

- Fault find and troubleshoot control system software

- Understand the value of data and using analytics to support predictive maintenance.

About your trainer

Dr Gary Allwood

Training and Operations Manager

Dr Gary Allwood is Training and Operations Manager at Skills Lab, responsible for developing and delivering industrial digitalisation micro-credentials and qualifications. Gary has a Bachelor's degree in physics and mathematics, and a first-class honours degree in physics, as well as a PhD in Engineering/Physics which focused on developing novel fibre optic-based sensors for industrial applications. Gary specialises in control engineering, SCADA, sensors, optical fibres and optoelectronics, completing several industry-recognised courses in industrial automation and control, and software engineering.

FAQs

At this time, there is no funding available for this micro-credential. Pricing information is available on this page.

Yes, our micro-credentials can be stacked, which means that learners can make continuous progress towards a certificate or diploma qualification, completed at a pace that suits you.

The USI is a code made up of 10 numbers and letters which is assigned to individual students and remains with the student for life. The USI is used to create a secure online record of your recognised training and qualifications awarded to you in Australia. You can access your online records by logging in onto the USI portal. Read more getting a USI here.

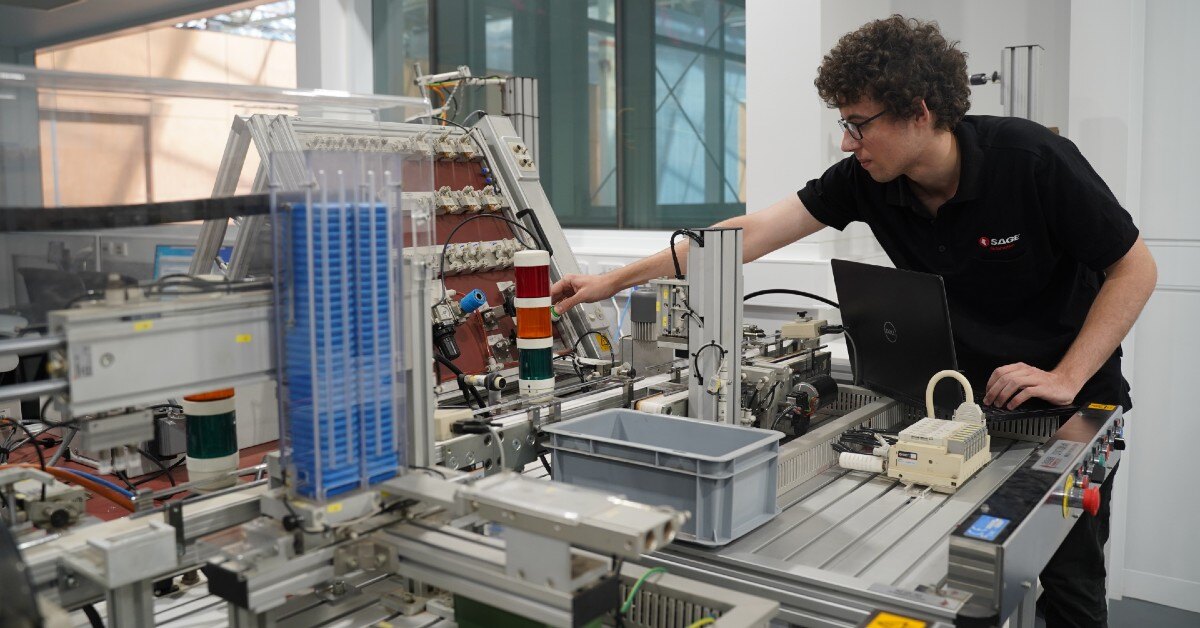

With our cyber physical training, you can complete the course from anywhere, as long as you have a reliable internet connection. Many users have found having two screens to be easier. Information on how to access training platforms will be emailed to you prior to the course commencing.

Related Courses

Electricians Working with Modern Industrial Automation | Skills Lab

This micro-credential equips learners with an understanding of the different hardware used in modern control systems, as well as the ability to troubleshoot the software and the incoming and outgoing signals.

Advanced Industrial Automation | Skills Lab

Nationally Recognised TrainingThis course looks at using the other three programming languages, Sequential Function Chart (SFC), Function Block Diagram (FB) and Structured Text (ST).

Programming Methods for Modern Industrial Automation | Skills Lab

Industrial automation has significantly changed in recent years through the convergence of operational technology (OT) and information technology (IT). Remote access to sites is now common practice as well as process data being stored in cloud-based systems.